This is Part Two of a Series, Interested in how Cacao Beans are grown and transformed into block chocolate? Check out part 1.

After the chocolate has been tempered into blocks, the chocolate manufacturers ship it to chocolatiers. The difference between a chocolate manufacturer and a chocolatier is that a chocolate manufacturer turns beans into 100% cacao chocolate blocks and a chocolatier turns those blocks into the tens of thousands of different chocolate confections we see out in the world. Some chocolate companies employ both chocolate manufactures and chocolatiers, to engage and control more of the chocolate making process. Different companies engage the process a little differently.

Once a chocolate block gets in the hands of the chocolatier, all sorts of magic starts to happen, and no two chocolatiers follow the exact same process.

To produce your average dark chocolate bar, a chocolatier chops and melts a block of chocolate, they then add a variety of ingredients. Milk and sugar are fairly standard in almost all chocolates, though some countries have a predisposition to add hazelnut pastes, butter, and vanilla in varying amounts. More cocoa butter can be added to a chocolate as well to make it lighter, which is the case in many Vegan chocolates. Everything from fruits to nuts to bacon can be added to the chocolate as well. Certain companies will use emulsifiers to influence the texture of the chocolate

A Chocolate Block starts as 100% cacao, and as a chocolatier adds more ingredients that percentage will fall. Many chocolate connoisseurs declare 72% as the perfect ratio to taste a dark chocolate. High quality American dark Chocolate tends to fall between 50% and 60%, though internationally 55% is considered a “light dark” or“deep milk”. Anything below 50% is safely considered milk chocolate, and most American milk chocolates fall between 20% and 30%.

A Chocolate Block starts as 100% cacao, and as a chocolatier adds more ingredients that percentage will fall. Many chocolate connoisseurs declare 72% as the perfect ratio to taste a dark chocolate. High quality American dark Chocolate tends to fall between 50% and 60%, though internationally 55% is considered a “light dark” or“deep milk”. Anything below 50% is safely considered milk chocolate, and most American milk chocolates fall between 20% and 30%.

Once a chocolatier has decided on a percentage and ingredients, they must re-temper the chocolate. Tempering chocolate is the fine process of giving a chocolate its shape, texture, and consistency. Scientifically speaking, chocolate is a quirky material to work with. Neither a solid, nor a liquid, chocolate is a combination of two colloids (cacao butter and cacao solids), known as a solid sol. Furthermore cacao butter has six different chemical forms it can take based on the molecular organization of the suspended particles. The six different forms are defined by their molecular crystals, Forms 1-4 have a tendency to melt or separate. If you’ve ever seen white splotches on a chocolate bar, you’ve seen a chocolate with the substandard 1-4 temper.

Properly tempered chocolate is mostly in Form 5, with some amount of Form 6 as well. Each different form has a different melting point, and fortunately the desirable Forms 5 and 6 melt at a much higher temperature than the substandard Forms 1-4.

Chocolate tempering is the process of melting the chocolate, then bringing the temperature hot enough so that Forms 1-4 melt, but Forms 5 and 6 have a chance to form. The chocolate has to be stirred constantly to maintain a consistent temperature throughout. Most large companies use chocolate tempering machines, though smaller versions are available for enterprising chefs. The chocolate must then be cooled quickly so that it can set before the wrong kinds of crystals can form. This is usually done with a cold water bath or cooled marble slab. After a chocolate is tempered, the form will set, so that the crystal structures won’t collapse as long as you keep the temperature below the melting point for Forms 5-6. This allows Chocolatiers to take already tempered chocolate and build it into all the many amazing forms that we know and love.

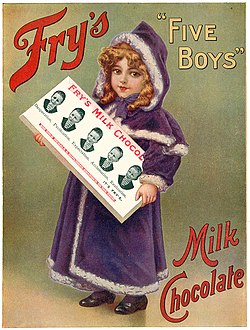

The history of tempering chocolate begins in England in 1847, where a company known as Fry & Sons developed the first solid chocolate bar. Fry & Sons later merged with the Cadbury Brothers to set the foundation of the English Chocolate Industry. England never colonized regions that grew cacao however, so all of their cacao beans had to be imported. Not long after in Brussels, a pharmacist by the name of Jean Neuhaus began developing chocolates as well. Belgium had recently colonized the African Congo, which had a near inexhaustible supply of cacao. With access to a higher quality beans, the Neuhaus Company developed the first chocolate truffles, filled chocolate shells.

The history of tempering chocolate begins in England in 1847, where a company known as Fry & Sons developed the first solid chocolate bar. Fry & Sons later merged with the Cadbury Brothers to set the foundation of the English Chocolate Industry. England never colonized regions that grew cacao however, so all of their cacao beans had to be imported. Not long after in Brussels, a pharmacist by the name of Jean Neuhaus began developing chocolates as well. Belgium had recently colonized the African Congo, which had a near inexhaustible supply of cacao. With access to a higher quality beans, the Neuhaus Company developed the first chocolate truffles, filled chocolate shells.

The development of chocolates has been continuous since its discovery, and chocolatiers are trying new methods and ingredients every day. The world of chocolate I in constant flux, and we at Gourmet Boutique hope you get the chance to enjoy every step of the way.